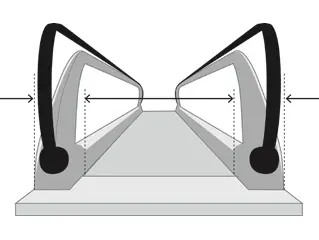

With its two-way flap system and additional skirt protector, iwalk’s unique handrail inlet stands up to the daily abuse of trolleys and carts. It eliminates unsightly brushes or rubbers and provides lasting good looks. Even better yet, a kick-resistant safety contact reduces stops, increasing iwalk’s availability.

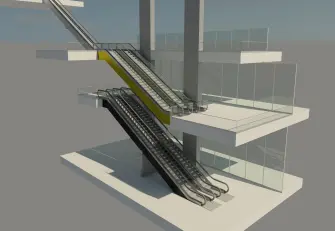

By revolutionising the way moving walks are designed, manufactured and installed, iwalk establishes a new industry benchmark. Its modular space-saving concept facilitates planning, integration and operation without compromising usability. For passengers travelling with luggage and trolleys, it offers greater safety and comfort. Fewer components and low energy consumption complete this sustainable product’s ground-breaking engineering.

iwalk. The next-generation moving walk today.

Key benefits

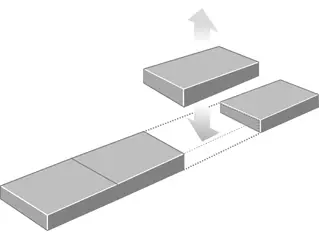

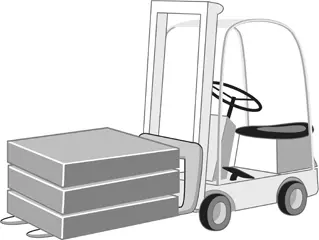

iwalk features standardised modules that are easily exchanged or replaced, making last minute changes a simple matter. Now even relocations are possible using just a forklift.

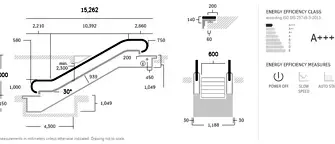

Compared to conventional designs, iwalk’s reduced outer dimensions and 30% lighter weight put less strain on your building, which means less reinforcement in the architecture.

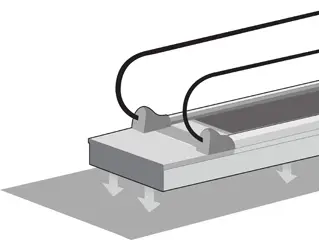

Choose between two configurations: one with a reduced pit depth or a pitless version that you can place directly on your finished floor. The benefits are yours, from minimal to no extra civil work, making iwalk ideal for any modernisation or replacement project.

iwalk’s two different pallet widths – 1,100 millimetre and 1,400 millimetre – enhance passenger comfort while their reduced outer dimensions require less building space.

iwalk boasts an eco-friendly design. The reduced total weight and stackable modules minimise transportation volumes and the related emissions. Energy-saving features such as its Energy Efficiency Controller and LED lighting enhance iwalk’s sustainability. So does the fact that, once this innovative product reaches the end of its service life, most of its parts can be recycled.

United Kingdom and Ireland

United Kingdom and Ireland