Traction Versus Hydraulic Elevators

From the world's tallest buildings to the deepest and most extreme mines, elevators are literally everywhere. They can be indoors, outdoors and even built into cliffs. Elevators are so important that people in North America ride them approximately 103 billion times per year!

But unless you’ve checked out the machinery behind the scenes, you might not be familiar with the two major types of elevators: traction and hydraulic.

So what’s the difference between traction and hydraulic elevators? And what does it mean for your building?

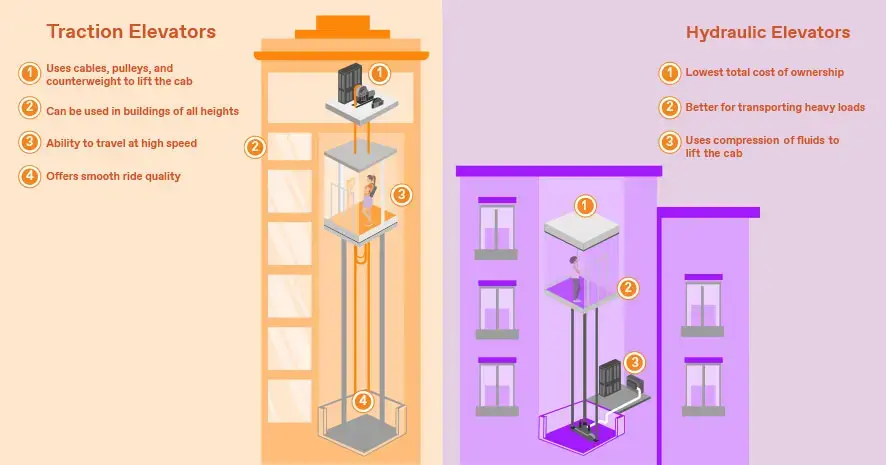

Traction elevators

With traction elevators (like the evolution 100 from TK Elevator) the elevator cab is raised and lowered by belts or steel ropes and a counterweight on a pulley system.

Traction elevators usually have gearless permanent magnet motors which provide power and efficiency in a compact size.

Hydraulic elevators

In contrast to traction elevators, hydraulic elevators (like endura MRL from TK Elevator) don’t use belts or ropes. Instead, they use an electronic pump to push hydraulic fluid into a cylinder, using pressure. This pressure pushes a piston and causes the elevator to rise.

Historically, hydraulic elevator fluid has been petroleum-based, but technological advancements have allowed environmentally friendly, biodegradable, rapidly renewable fluid to be used that can actually improve elevator performance.

Traction elevator advantages

Appreciated for their smooth ride quality and ability to travel at high speeds, traction elevators are typically used in buildings with over 60 feet of travel, up to the world’s most iconic skyscrapers.

Because traction elevators use a counterweight to offset the weight of the cab and occupants, the motor doesn’t have to move as much weight. This makes traction elevators more energy efficient than hydraulic elevators in higher-rise, heavy-use applications.

Hydraulic elevator advantages

A proven technology in use for more than 50 years, hydraulic elevators are used in buildings with under 60 feet of travel. They typically have lower installation costs than traction elevators and fewer moving parts, which can reduce maintenance and repair costs. Hydraulic elevators use less energy while waiting, and almost no power while lowering the cab. Therefore, in low-use, low-rise applications, hydraulic elevators can use less energy than traction elevators. Because of these benefits, hydraulic elevators can have a lower embodied and operational carbon footprint.

While hydraulic elevators can’t reach the fast speeds achieved by traction elevators, in low-rise applications they are adequate, and can carry heavier loads efficiently.

In past decades, hydraulic elevators required holes to be drilled into the ground, in which hydraulic fluid cylinders were extended and placed into the drilled hole. However, technological advancements have created totally-above-ground hydraulic elevators powered by telescopic jack units mounted to the pit floor, which can travel approximately 33 ½ feet.

What’s the best type of elevator for your building?

You’ve waited for the big question and answer! While each building’s demands are unique, the right elevator choice for your building could depend on what your building is used for, or what meets your tenant needs.

Let us assist with your building design by providing expert traffic analysis and energy studies. Following these, a TK Elevator sales rep can help lead you to the right solution. Contact us to begin the process.

United States

United States