The walls of an elevator cab are primarily built for safety, but they also play an important role in the continuation of a building’s design and general aesthetic. Here are some of the most common cab wall types.

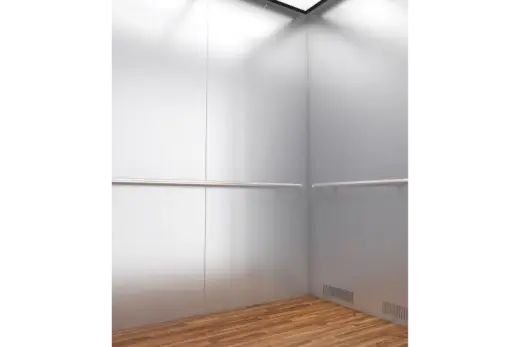

Flat Steel Wall

A common choice, these walls are constructed of steel and create a completely flat interior for the cab. This is a fairly standard option and can have brushed, polished or patterned stainless steel or a durable scratch-resistant powder coat finish.

Applied Panel

These cab walls are constructed with a high-quality steel shell and vertical or horizontal raised panels made with a core of particle board. Just as the name implies, the panels are applied onto the standard steel panel and are often finished with wood, veneer or laminated plastic.

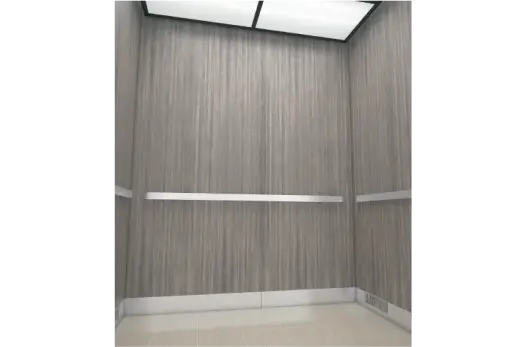

Laminated Plastic

Laminated plastic cabs have wood core walls faced with high-pressure laminate. These laminates can be made in various solid colors, patterns or wood grain to closely match the aesthetic of a building and improve the overall passenger experience.

United States

United States